Find a solution that fits you

Industry Segments

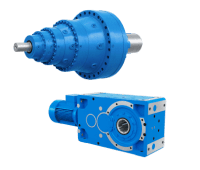

Planetary gear reducers

PRODUCTS

Discover our product range

Industrial Gear Units

A wide range of gear reducers, combined with a high level of engineering expertise, decades of experience...

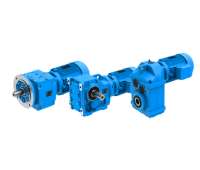

Gearmotors

If compared to those on the market today, Rossi boosts one of the broadest ranges of gear reducers and gearmotors...

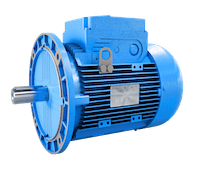

Electric Motors

Satisfy all the customers' requests, assuring a high-quality standard: this is the permanent objective of our skilled department...

Motion Control

Decentralized inverter, designed to be installed directly on Rossi high-efficiency electric motors with gearboxes...

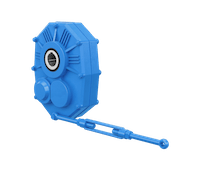

Other Products

One of the most complete product ranges on the market allows us to choose gear reducer or gearmotor that best suits you...

Stay connected with us

Rossi @ AQUA 2024

Next appointment March 19-21, 2023 | Evenementenhal Gorinchem (Netherlands)

More Details

Environmental report 2022

More Details

"Il Sole 24 Ore" celebrates 70 years of the Rossi Group and future investments

More Details

Rossi India: Great Place to Work® certified

More Details

Discover the new Rossi Online Configurator: it's time for customization!

More Details

New Recycling and Wastewater Treatment brochure

Learn about the applications and technical features of our gearmotors

More Details

Rossi @ FENASUCRO 2023

Next appointment 15-18/08/2023 | Centro de Eventos Zanini (Sertãozinho)

More Details

70 years of history

More Details

iFit series conforming to market standard, offering better delivery times: only 2 working weeks!

More Details

iFit series conforming to market standard, offering better performance

More Details

Season's greetings 2022

More Details

Rossi increases productivity in the steel processing

More Details

Environmental report 2022

More Details

"Il Sole 24 Ore" celebrates 70 years of the Rossi Group and future investments

More Details

Rossi India: Great Place to Work® certified

More Details

Discover the new Rossi Online Configurator: it's time for customization!

More Details

New Recycling and Wastewater Treatment brochure

Learn about the applications and technical features of our gearmotors

More Details

iFit series conforming to market standard, offering better delivery times: only 2 working weeks!

More Details

iFit series conforming to market standard, offering better performance

More Details

Season's greetings 2022

More Details

Rossi increases productivity in the steel processing

More Details

Rossi @ AQUA 2024

Next appointment March 19-21, 2023 | Evenementenhal Gorinchem (Netherlands)

More Details

Rossi @ FENASUCRO 2023

Next appointment 15-18/08/2023 | Centro de Eventos Zanini (Sertãozinho)

More Details

.jpg?h=600&iar=0&w=800&hash=DF3563371B147ABA56CFE702183357E7)

.jpg?h=600&iar=0&w=800&hash=302B0AB4114C9F0870DC21E91603866D)

.jpg?h=600&iar=0&w=800&hash=F8C57426FDE5EE1D02B14DC178B61AFF)

.jpg?h=600&iar=0&w=800&hash=1D5CD67B9D0BDCCE1F13BA6A35C1C959)

.jpg?h=600&iar=0&w=800&hash=8B1096A6B7046C395D6D4105F2F9CA4A)

.jpg?h=600&iar=0&w=800&hash=231CB6696ED8B0A590760789826C7961)

.jpg?h=600&iar=0&w=800&hash=9B5CFF7EC12EDFBE36C041B73A22F3F8)

.png?h=600&iar=0&w=800&hash=B56F6D4FD76C4AF377CEA87E3E23A63F)